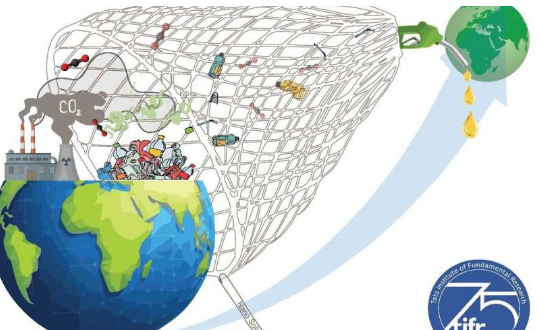

The primary cause of climate change is atmospheric CO2, and levels are rising every day. There is, therefore, a great need to find ways to reduce CO2levels. On other hand, an excessive amount of plastic waste has become a serious environmental problem. In this work, published inNature Communications, researchers dealt with both problems at one stroke, by developing nano solid acids that transform CO2directly to fuel (dimethyl ether) and plastic waste to chemicals (hydrocarbons).

Solid acids are among the most essential heterogeneous catalysts, which have the potential to replace environmentally harmful liquid acids in some of the most important processes, such as hydrocarbon cracking, alkylation, as well as plastic waste degradation andcarbon dioxideto fuel conversion.

Two of the best-known solid acids are crystalline zeolites and amorphous aluminosilicates. Although zeolites are strongly acidic, they are limited by their inherent microporosity, causing extreme diffusion limitation; and although aluminosilicates are mesoporous, they suffer from low acidity and moderate stability. Thus, it is a synthetic challenge to design and synthesize solid acids with both strong acidities like zeolites and textural properties like aluminosilicates, speculated as "amorphous zeolites," which are ideally strongly acidic amorphous aluminosilicates.

On the other hand, the effect of global warming in terms of drastic changes in weather patterns due to rising CO2is already clearly visible and alarming. There is, therefore, a great need to find ways to reduce carbon dioxide levels, either by sequestering it or by converting it to fuel.

By using the techniques of bicontinuous microemulsion droplets as a soft template, Prof. Vivek Polshettiwar's group at Tata Institute of Fundamental Research (TIFR), Mumbai, synthesized amorphous zeolites with a nano-sponge morphology, exhibiting both zeolitic (strong acidity) and amorphous aluminosilicate (mesoporous high surface area) properties. The presence ofzeolite-like bridging silanol in AAS was proved by various catalytic reactions (styrene oxide ring-opening, vesidryl synthesis, Friedel-Crafts alkylation, jasminaldehyde synthesis, m-xylene isomerization, and cumene cracking), which requires strong acidic sites and larger pore sizes. The synergy between strong acidity and accessibility was reflected in the fact that AAS showed better performance than state-of-the-art zeolites and amorphous aluminosilicates. This was also confirmed by detailed solid-state NMR studies. Thus, it was clear that the material possesses strongly acidic zeolite-like bridging silanol sites, even though materials are not crystalline but amorphous. Therefore, they fall into a new class of materials at the interface between crystalline zeolite and amorphous aluminosilicate.

Thus, the approach may allow the development of solidacidcatalysis for plastic degradation as well as carbon dioxide to fuel at the significant rates, scales, and stabilities required to make the process economically competitive. The protocol has scientific and technological advantages, owing to its superior activity and stability.

Explore further

Researchers develop hollow ZSM-5 zeolite catalyst with low silicon to aluminum ratio

More information:Ayan Maity et al. Catalytic nanosponges of acidic aluminosilicates for plastic degradation and CO2 to fuel conversion,Nature Communications(2020).DOI: 10.1038/s41467-020-17711-6

Journal information:Nature Communications

Provided byTata Institute of Fundamental Research