A research group coordinated by physicists of the University of Trento was able to probe internal stress in colloidal glasses, a crucial step to controlling the mechanical properties of glasses. Their work opens the way to new types of glass for new applications. The study was published in Science Advances.

Glasses used for camera lenses or reading glasses are not like those used to make windshields. They have a different degree of transparency and they break in a different way (the former break in large pieces, the latter in a multitude of tiny pieces). The techniques to obtain glasses with specific properties have long been known to the industry: a slow process for optical applications, tempering for glasses designed to break safely. These procedures determine the stress within the glass, which can therefore be easily minimized or maximized. But how to control the stress stored in a glass to adjusts it to our needs? If we could do that, we would be able to design new types of glass for new applications.

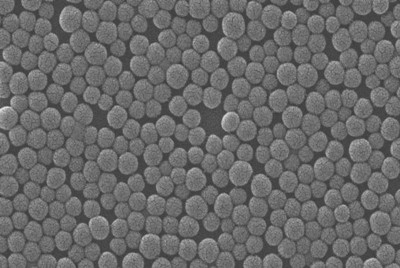

That is the question a research group of UniTrento, made up of physicists, tried to answer. The researchers focused on colloidal glasses, which are made up of microscopic particles dispersed in a solution at a concentration that allows the formation of a compact solid. The physicists of the University of Trento conducted a number of experiments at the Petra facility in Hamburg (Desy, Deutsches Elektronen-Synchrotron), Germany, and managed to create colloidal glasses characterised by a unidirectional stress, that is to say that the stresses stored locally in this material during the formation are all heading in the same direction. The results of the study were published in Science Advances.

Giulio Monaco, director of the Department of Physics of the University of Trento and coordinator of the research work, said, "Colloidal glasses are relatively stable. Think about window glass, that can last for centuries. However, locally, the atoms and particles are subject to heavy stresses, whose intensity, distribution and direction determine the mechanical properties of the material. It would be very useful if we could control those stresses."

He continued: "Measuring the intensity and direction of the stress stored in a glass is a crucial step to control these forces and therefore use them in industrial applications."