Silicon is abundant in nature with high theoretical capacity (4200 mAh g-1), making it an ideal anode material for improving the energy density of dual-ion batteries (DIBs). However, its application in DIBs has been restricted by the large volume expansion problem (>300%).

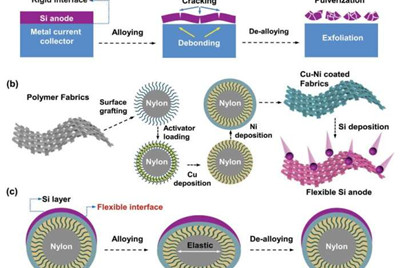

Rigid contacts between silicon and current collectors, commonly made with metal foils, lead to significant interfacial stress. As a consequence, interface cracking and even exfoliation of active materials occur resulting in suboptima cycling performance.

A research group led by Prof. Tang Yongbing and his team members (Dr. Jiang Chunlei, Xiang Lei, Miao Shijie etc.) from the Shenzhen Institutes of Advanced Technology (SIAT) of the Chinese Academy of Sciences, along with Prof. Zheng Zijian from the Hong Kong Polytechnic University, have proposed a flexible interface design to reduce alloying stress on silicon anodes in silicon-graphite DIBs.

This flexible interface design modulates stress distribution via the construction of a silicon anode on a soft nylon fabric modified with a conductive Cu-Ni transition layer, thus endowing the silicon electrode with remarkable flexibility and stability over 50,000 bends.

Assembly of the flexible silicon anode with an expanded graphite cathode yielded a silicon-graphite DIB (SGDIB) having record-breaking rate performance (up to 150 C) and cycling stability over 2000 cycles at 10 C with capacity retention of 97%.

Moreover, the SGDIB showed high capacity retention of about 84% after 1500 bends and a low self-discharging voltage loss of 0.0015% per bend after 10,000 bends, indicating strong potential for high-performance, flexible energy-storage applications.