A team of researchers from the Chinese Academy of Sciences and the University of Cambridge has found a way to rejuvenate metallic glass to prevent it from fracturing. In their paper published in the journal Nature, the group outlines their process and proposed uses for the rejuvenated metallic glass.

Metallic glasses are metals that have an internal structure that is similar to glass—instead of a crystal structure, they are non-periodic. They are made by heating alloys to their melting point and then cooling them in ways that prevent crystallization. Material scientists are interested in them because they have unusual mechanical properties such as exceptional strength. But they also have a major weakness—under extreme stress, they can soften during deformation, leading to catastrophic failure. In contrast, with normal metals, stress results in hardening when plastic deformation occurs, preventing the entire structure from coming apart. In this new effort, the researchers have developed a way to make metallic glass behave in the same way.

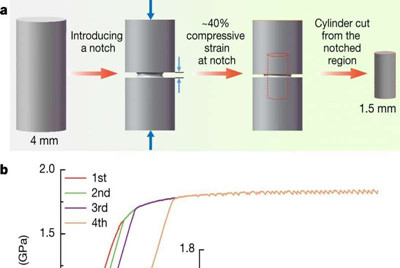

In their work, the researchers demonstrated that deformation during triaxial compression could rejuvenate metallic glass samples enough to allow strain hardening in a way that had not been observed in a metallic state before. In so doing, they discovered that with strain hardening, shear banding on the sample surface could be prevented. They also found that after rejuvenation, the first halo shifted back toward a higher scattering vector magnitude after deformation. And they found that the initial rates of hardening from the sample were much higher than for crystalline alloys, which showed that the mechanism they used was very efficient.

The researchers noted that the work-hardening observed in the sample was made possible by proliferating defects that impeded gliding during deformation. They further noted that for bulk-metallic glass applications, work-hardening is based on reductions in energy, as opposed to the energy increases seen in crystalline metals—a difference that highlights the novelty of the mechanism they used to strain-harden their metallic glass sample.

Testing the process showed the metallic glass samples to be stable at room temperatures, and the samples had efficient strain-hardening, which increased the possibility of commercial applications.