In a circular economy, city waste being turned into resources is of great importance, considering that more than 70% of the inhabitants in Europe live in urban areas and produce a great amount of biowaste coming from the treatment of their waste waters. The European project RES URBIS (Resources from Urban Bio-waste), showed that different biowaste produced in an urban environment can be treated within the same chain of valorisation and can obtain products with biological origins, such as bioplastic, with a higher economic value to classic compost and biogas processes. The project confirmed the technical and economic viability of this process.

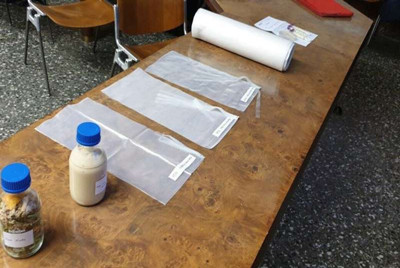

The experimental part of the project was carried out in two pilot plants, located in Lisbon (Portugal) and Treviso (Italy), and in five laboratories—one of them in the Faculty of Chemistry of the UB. It produced a total of 30 kg of polyhydroxyalkanoates (PHA), the basic polymer to create bioplastic with volatile fatty acids from waste decomposition. This PHA was obtained through three new extraction methods carried out within the project, and later, processed by the industrial entities of the consortium to obtain commercial-use bioplastic.

"The results of the project were very positive. We obtained film samples of bioplastic to use them as an interlayer with adjacent film, with a great commercial potential. These bioplastics can be used as long-lasting goods and biocomposites with fibres produced with waste from parks and gardens," says Joan Mata, professor from the Department of Chemical Engineering and Analytical Chemistry, who leads the participation of the University of Barcelona in the project. "Also," he adds, "the conducted analysis shows what the legislation states."

Regarding commercialization of these bioplastics, the team considered the European regulatory frame on the potential risks for health and environment of chemical products (REACH-CLP), and although there is still a lot to do on the definition of the final condition of the product known as waste final, "the scenario for the commercialization of the product is highly favourable," notes Mata.

More efficient refineries with a lower environmental impact

The analysis of the life cycle of these bioplastics showed that the materials and energy used by PHA production through the presented biorefinery in the RES URBIS project have a lower environmental impact than the ones generated by plastic production from fossil origin.

The RES URBIS technological chain improved the plants on anaerobic digestion of biowaste. Its economic analysis in the analysed scenario —among which is the Metropolitan Area of Barcelona—shows the production of PHA is viable after a price of 3€/kg and even less if considering the most favourable conditions of the process. This price, compared to the price of the current commercialized PHA obtained from specific cultures of cereals with a 4-5€/kg cost, shows the economic viability of the process.

"The following step will be to get funding through the EU and the private sector to build a demonstration plant," says Mata.