In a recent report on Nature Communications, Wentao Gan and a team of researchers at the departments of materials science and engineering in the U.S. have detailed the use of an ultrathin film of natural wood to create an audio speaker. The construct exhibited excellent mechanical properties including high tensile strength and increased Young's modulus. The properties of ultrathin thickness and exceptional mechanical strength allowed excellent acoustic properties with higher resonance frequency and greater displacement amplitude when compared to a commercial polypropylene diaphragm in an audio speaker. As proof of concept, Gan et al. directly used the ultrathin wood film as a diaphragm in a real speaker to emit music. The surfaces with excellent mechanical properties and acoustic performance were a promising candidate to build next-generation acoustic speakers.

Thin films in the scale of microns to nanometers in thickness have multifunctional applications in solar cells, food packaging, water treatment, personal electronics and as acoustic sensors. Acoustic membranes are typically very thin (micron-scale) and mechanically robust with a high modulus to allow a highly sensitive frequency response and high vibrational amplitude. Physicists and engineers have dedicated tremendous efforts in the past decades to develop a variety of acoustic thin film materials based on plastic, metal, ceramic and carbon to enhance the quality of sound.

Plastic thin films are used ubiquitously in commercial speakers due to low cost and ease of manufacture, however, they impose an enormous environmental impact due to ineffective degradation. Metal, ceramic and carbon-based materials also demonstrate higher modulus compared to plastic film to improve the frequency response of the acoustic membrane. These components generally cost higher and require complex, energy consuming manufacturing processes. As a result, it is desirable to develop a biodegradable, acoustic thin film for green and cost-effective applications.

Morphology and chemical characterization of the wood films

Natural cellulose-based materials such as bagasse, wood fibers, chitin, cotton, bacterial cellulose and lignocellulose provide an environmentally friendly platform to manufacture thin films rapidly without using limited fossil resources. The natural structure of wood is an effective alternative for more scalable and mechanically robust cellulose films. Wood can be used as a scaffold to construct thin films in a top-down approach in a scalable and cost-effective process compared to bottom-up methods. Maintaining the alignment of cellulose fibers will allow robust mechanical properties in the resulting material. Wood is also renewable, biodegradable and environmentally sustainable compared to plastics and metal.

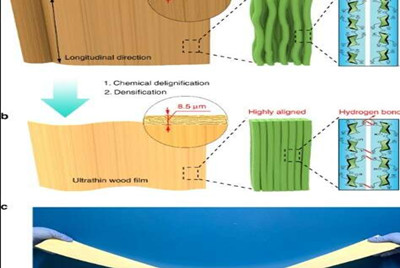

To build the ultrathin film with a thickness as low as 8.5 micrometers in the present work, Gan et al. partially removed lignin (delignification) and hemicellulose from natural balsa wood. They generated a highly porous material, which retained most of the cellulose in the cell walls, followed by increasing the density of treated wood by hot pressing for a thickness reduction of 97 percent. The densely packed wood cell wall structure combined with highly aligned cellulose fibers, contributed to superior tensile strength and high Young's modulus. The research team used industry-based cutting methods to develop a meter-long natural balsa wood film in the lab to reveal the material's potential for large-scale manufacture via a top-down approach.

Gan et al. cut the natural wood along its longitudinal direction to maintain the channel structure and observed the microscopic structures using scanning electron microscopy (SEM). The cellulose nanofibers in the ultrathin wood film remained highly oriented but more densely laminated compared to natural wood. X-ray diffraction (XRD) analysis indicated retention of the molecular alignment and crystal structure of the cellulose nanofibers, which was important for the material's mechanical properties.

To understand the material's mechanical properties, the research team conducted mechanical tensile tests. Ultrathin wood showed greatly improved mechanical behavior compared with natural wood, with increased fracture strength of up to 342 MPa and Young's modulus of 43.65 GPa. These values indicated an almost 20-times improvement in tensile strength and 35-times enhancement in Young's modulus compared to natural wood.

The scientists were keen to understand the underlying mechanisms. For this, they used SEM observations and demonstrated a porous microstructure with numerous wood channels in the natural wood slice after tensile tests. The feature made it easier to pull loosely assembled wood during tension; explaining the naturally low fracture strength observed. In contrast, wood cell walls within the synthetic ultrathin wood film formed hydrogen bonds between the firmly compressed cellulose nanofibers after densification; requiring higher energy to be pulled apart.

The high tensile strength and Young's modulus of the ultrathin film also exceeded typical plastic and natural biomaterials to validate its excellent mechanical properties. The exceptional flexibility and foldability allowed research teams to develop a variety of origami designs. In contrast, the brittle natural wood did not demonstrate such malleability. The foldability also highlighted potential uses of the ultrathin wood films for photonics, acoustic sensors and flexible electronics devices. The high Young's modulus and ultrathin nature of the wood film helped increase the resonance frequency and enhance displacement amplitude of the diaphragm vibration. These characteristics strongly suited the ultrathin wood film's applications as a diaphragm for acoustic transducers with a wide operation bandwidth, with high sensitivity for microphones and high sound pressure levels for speakers.

The new construct formed an attractive alternative to conventional polymer films, allowing the ultrathin wood film to become highly suitable for acoustic transducers with a wide operation bandwidth, high sensitivity and high sound pressure levels. To confirm the properties of increased resonance frequency and displacement, the team tested the frequency response of the ultrathin wood compared to a conventional polymer film. The results were highly desirable as high-performance acoustic transducers.

Gan et al. demonstrated promising applications of the ultrathin wood films as an acoustic transducer to assemble a miniature speaker. The prototype contained a wood diaphragm and a circuit board with a miniature speaker, containing a copper coil and permanent magnet. The setup facilitated electromagnetic forces to act on the coil and cause the diaphragm to vibrate back and forth. They translated the electrical signal into an audible sound, as a result of the air pressure caused by the diaphragm and recorded the audible sound of the speaker prototype using a microphone and soundwave, which they analyzed using Adobe Audition CC. The research team used the speaker to play a recording of the Spain Matador March. They expect to further improve the diaphragm structure design and precise assemblies within the existing industrial process. The sustainable technology can be translated into the manufacture of microphones, hearing aids and acoustic sensors.

In this way, Wentao Gan and colleagues developed and demonstrated an effective top-down strategy to engineer an ultrathin wood film less than 10 micrometers in thickness after subjecting natural wood to delignification and densification. They observed a unique microstructure for the ultrathin wood film with intertwined wood cell walls and aligned cellulose nanofibers, which contributed to outstanding mechanical properties relative to improved tensile strength and Young's modulus. The research team achieved a high-performance acoustic transducer with increased resonance frequency and enhanced displacement amplitude. The green loudspeaker prototype generated music due to vibrations of the ultrathin wood diaphragm with wide-ranging acoustic applications of the material. The research team envision the technique will open additional functions and applications for strong film materials using sustainable and biodegradable natural resources to replace plastic, metal and ceramics.